McHale Balers

View the McHale Integrated Baler/Wrappers, Fixed-Chamber Balers, and the Variable-Chamber Balers here. McHale products are manufactured in Ireland and live up to every expectation.

“Recognized worldwide for…performance and reliability”

Fusion McHale Balers

The McHale Fusion Baler is an integrated baler and wrapper in one unit. McHale offers fixed chamber and Variable chamber balers as Fusion balers.

Fixed Chamber Balers

Fixed chamber balers are offered in three different baler configurations. The standard fixed chamber, a fixed chamber chopper baler, and a film binding baler.

Variable Chamber Baler

McHale Variable Chamber balers are offered in four different configurations: the V6 chopper and non-chopper balers and the V8 chopper and non-chopper balers.

The V6 Variable Chamber Round Baler Range has been designed with the demands of today’s farmer and contractor in mind. This common sense approach to design ensures that their operation is kept simple and user friendly. All the balers in the V6 Variable Chamber baler range makes bales from 2′ 4″ up to 5′ 6″.

The McHale V6740 is a non-chopper variable chamber baler that is equipped with a high intake feed rotor to ensure even and efficient crop flow to the bale chamber.

The McHale V6740 is driven by a primary drive system for optimum bale formation. ventral grease blocks are fitted on the machine for greasing whilst oiling is controlled through the continuous oil system. Net and bale density can be adjusted from the cab though the Expert PLUS control console.

The McHale V6750 is a semi-automatic variable chamber baler which is fitted with a 15-knife chopper unit and heavy-duty roller. It is equipped with a double drive system which allows the machine to operate in the toughest of conditions. The double drive system aids belt rotation and bale formation.

The machine comes with centralized grease blocks as standard. Automatic greasing is available as an option on all V6750 machines. Net and bale density can be adjusted form the cab though the Expert PLUS control console.

The McHale V8940 is a high-capacity, non-chopper variable chamber baler capable of producing bales from 2′ to 6′ 3″. It is equipped with a high intake feed rotor to ensure even and efficient crop flow to the bale chamber.

The V8940 is driven by a primary drive system for optimum bale formation using 3-endless belts. Central grease blocks are fitted on the machine for greasing whilst oiling is controlled through the continuous oiling system which is driven from the gearbox. Net and bale density can be adjusted through the Expert Plus Control Console.

The McHale V8950 is a semi-automatic variable chamber baler which is fitted with a 15 knife chopper unit and heavy-duty rotor. It is equipped with a double drive system which allows the machine to operate in the toughest of conditions. The double drive system aids belt rotation and bale formation.

The machine comes with centralized grease blocks as standard. Automatic greasing is available as an option on all V8950 machines. Net and bale density can be adjusted from the cab through the Expert Plus control console.

McHale offers four balers in its F5000 fixed baler range, three Net Binding and on Film Binding baler. All the balers in the McHale F5000 fixed chamber baler range make bales 4′ 2″ by 4′ 1″.

Individual models are F5400, F5500, F5600, and F5600 PLUS. Non-chopper units, 15-knife choppers, and 25-knife chopper net baler and 25-knife chopper film baler.

The McHale F5400 non-chopper round baler features a star shaped feed rotor to quickly and efficiently move the crop from the pick up into the bale chamber. This maximizes the baler performance and throughput.

The F5400 non chopper round baler comes standard with the McHale Drop Floor Unblocking System, 50mm Bearings on the bale chamber, heavy-duty chains and a continuous oiling system.

Roller Sealing System

The roller ends are fitted with a McHale-designed reverse thread sealing system. This system protects the bearings; when the roller moves in one direction the thread on the seal moves in the opposite direction. This ensures that any material which tries to get into the back of the rollers is automatically threaded out.

Roller Sealing System

The roller ends are fitted with a McHale-designed reverse thread sealing system. This system protects the bearings; when the roller moves in one direction the thread on the seal moves in the opposite direction. This ensures that any material which tries to get into the back of the rollers is automatically threaded out.

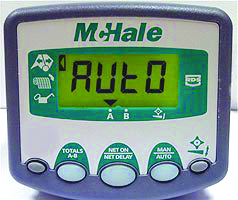

Wizard control box

The F5400 is equipped with a Wizard control box containing all the functionality required to operate the machine. The control box displays job and machine totals, a net feed and delay functions and also has a lube count alarm to remind the operator to check the oil levels and to grease the machine.

Drop floor

The McHale F5400 non chopper round baler is designed to achieve maximum output, however as baling conditions are not always ideal, uneven swarths can occur, which can lead to blockages. The main drive chain is protected by a slip clutch on the PTO.

Should a blockage occur, the sound of the slip clutch alerts the operator who can hydraulically lower the floor from the tractor cab. This widens the feed channel, on re-engaging the PTO the blockage will be fed through. The floor can then be reset and baling can resume.

Split Drive Gearbox

On the McHale F5400 Non Chopper Round Baler, the left hand side of the gearbox drives the rollers in the bale chamber, while the pick up and feed rotor are driven from the right hand side of the machine. This system ensures direct short transfer paths and optimal power distribution.

Feed rotor

The star shaped feed rotor fitted behind the pick up on the F5400 round baler ensures a high capacity flow of grass into the bale chamber. As crop enters the rotor, rotating tines feed the crop through to the bale chamber. The tines on the rotor ensure high output while the star layout reduces the load peaks as the F5400 round baler works in heavy swaths.

Net loading & storage

Net loading has been optimized on the F5000 baler range by the simple yet very effective rock and roll net loading system. The operator simply releases the straps on the spare roll of net on the machine platform and rocks the net roll from its storage position over the lip in the platform and rolls it into the net box. Storage for an extra roll of net is provided on the baler platform.

Pick up

The McHale F5400 non-chopper round baler is equipped with a 2.1 meter galvanized pick up that lifts even the shortest of crop. Accurate height control can be achieved through a spring balanced hydraulic lifting system. The F5400 non chopper baler comes standard with pneumatic guide wheels, which contact the ground on exactly the same line as the tines and guide the pick up perfectly over uneven ground.

The pick up on the F5400 non-chopper baler is fitted with lateral feed augers that smoothly guide the crop into the chopping unit. The pick up features

A crop compression roller is also available as an optional extra on the McHale F5400 round baler. This roller evens out lumps in the swath and minimizes the risk of blockages when working in heavy swaths.

bale chamber / chamber bearings

The bale chamber on the McHale F5400 round baler produces a 1.23 X 1.25 meter round bale. The bale chamber on the F5400 round baler is comprised of 18 heavy duty rollers.

The 18 rollers in the bale chamber of the F5400 round baler are made from high-grade tubular steel for maximum strength, while roller design ensures maximum traction. The roller ends are fitted with heavy-duty 50mm shafts on the drive and non-drive side.

The rollers on the McHale F5400 round baler are fitted with 50mm bearings on the drive and non-drive side. Drive side rollers, which experience the most load, are fitted with double raced bearings.

vario stretch net system

A new high performance netter has been designed and developed for the F5000 range.

The net tension can be simply adjusted on a variable pulley on the right hand side of the machine and a decal displays the various settings that can be achieved using the system, depending on the net quality being used. This netter is very reliable and features:

The McHale F5500 is a 15 knife chopper baler. It has automatic progressive greasing and has a Wizard PLUS control box. Net and bale density can be adjusted on the machine. The machine is fitted with 500/50-17 tires as standard.

The McHale F5600 is a 25 knife chopper baler fitted with a servo operated load sensing control valve, which makes the baling process fully automatic. The baler has an Expert PLUS control console with a large graphic display. Bale density and net can be adjusted in-cab. The baler’s tailgate will automatically open when the bale is netted and will close when used in auto-cycle.

Film on film technology refers to the application of film to the barrel of the bale in the bale chamber. The film binds the bale together which eliminates teh need for string or net wrap. The film that binds the bale together forms a wrap layer and gives better film or plastic coverage on the largest surface of the bale.

The McHale F5600 PLUS is fitted with a servo operated load sensing control valve, which makes the baling process fully automatic. The machine is also equipped with a 25 knife chopping unite and an in chamber bale binding system.

McHale offers three balers in its Fusion Integrated Baler Wrapper Range. All the balers in the Fusion Integrated Baler Wrapper Range deliver a 4′ by 4′ 1″ bale except for the Fusion Vario which can make a bale sized anywhere from 2′ up to 5′ 6″ depending on the crop type you are baling.

Standard features include: compact size and superior maneuverability, 7′ pick up with 5 tine bar, drop floor unblocking system, heavy duty chains and bearings, patented bale transfer, high speed vertical wrapping wring, net wrap bale binding, and film bale binding* (*only available on Fusion 3 PLUS)

Check out the specs on each McHale baler below. The Fusion Vario, Fusion 3, and the all-new Fusion 4 fixed chamber baler and wrapper combo baler.

The McHale Fusion Vario is a fully integrated baler wrapper, which consists of a high output variable chamber baler with an integrated wrapping ring. It can produce various bale sizes depending on the crop in which it is operating.

The Fusion Vario is a machine which can work in all types of crops and gives the flexibility to make various sizes of bales depending on customer requirements, without having to change machines.

The McHale Fusion 4 is a fully automatic, integrated baler wrapper recognized worldwide for its unique patented bale transfer, vertical wrapping ring and high output. The machine is equipped with a 25 knife-chopping unit.

The new McHale Fusion 4 range has been developed with a focus on operator comfort and machine performance, while still ensuring the renowned simplicity and reliability is maintained.

Our specialist team of engineers have maximized machine intake and output, increased bale density and reduced maintenance intervals to ensure the Fusion 4 range of machines surpasses all your baling and wrapping expectations. These levels of comfort, when paired with proven features such as the patented bale transfer system and the vertical wrapping ring, enable the McHale Fusion 4 range of machines to offer durability, reliability and high-output to the end user.

PATENTED BALE TRANSFER

When the netting process is complete the bale chamber splits horizontally. As the top section of the bale chamber moves up, the lower section of the bale chamber simultaneously moves up and out, transferring the bale onto the wrapping platform.

VERTICAL WRAPPING RING

The vertical wrapping ring is fitted with two 750 mm dispensers, which take approximately 18 seconds to apply 4 layers of film and approximately 24 seconds to apply 6 layers of film. This means that the wrapping platform is always waiting for the next bale.

WRAPPING

Once the bale chamber is closed, wrapping will automatically start and baling can resume, delivering maximum output.

CONTROL CONSOLES

The Fusion 4 is equipped with an Expert Plus control console, which features a large graphic display; this allows the operator to monitor the baling process graphically from the control console.

The McHale Fusion 4 Pro is a fully automatic machine that uses net to bind the bale in the chamber and possesses a host of new features to maximize operator comfort. ISOBUS software provides the operator with in-cab net and density adjustment, camera options and a wide variety of useful data features.

The new McHale Fusion 4 range has been developed with a focus on operator comfort and machine performance, while still ensuring the renowned simplicity and reliability is maintained.

Our specialist team of engineers have maximized machine intake and output, increased bale density and reduced maintenance intervals to ensure the Fusion 4 range of machines surpasses all your baling and wrapping expectations. These levels of comfort, when paired with proven features such as the patented bale transfer system and the vertical wrapping ring, enable the McHale Fusion 4 range of machines to offer durability, reliability and high-output to the end user.

IN-CAB ADJUSTMENT

The ISOBUS control console allows for bale density to be adjusted from the comfort of the tractor cab. Depending on the crop and conditions, the operator can also adjust the number of layers of net on the control console.

DROP FLOOR UNBLOCKING

The drop floor unblocking system is fitted with an automatic unblocking function as standard. When connected to an ISOBUS tractor, the Auto Unblock feature lowers the floor when a blockage is detected. Once the operator restarts the PTO and clears the blockage, the drop floor will raise to its original position.

AUTO KNIFE DROP

In order to facilitate various feeding methods, McHale have developed a system allowing the outside of the bale not to be chopped. This allows the operator to chop the forage until the bale is almost complete, at which point the machine will automatically lower the knives. This improves machine intake and aids fodder distribution for the farmer.

CONTROL CONSOLES

The McHale Fusion 4 Pro is fitted with ISOBUS as standard. For customers without an ISOBUS tractor, an optional ISO-PLAY 7 or ISO-PLAY 12 terminal can be used. Through the ISOBUS tractor’s terminal or McHale’s ISO-PLAY consoles, the operator is provided with clear indicators of machine performance and allows for increased levels of monitoring, through the graphic display.

CAMERA DISPLAY AS STANDARD

The McHale Fusion 4 Pro comes fitted with a camera as standard to monitor the transfer and wrapping operation at the rear of the machine. When using an ISO-PLAY terminal, this camera automatically displays on the control console in the tractor cab when the bale is being transferred to the wrapping table, at the beginning of the wrapping cycle and when the bale is about to be tipped.

The McHale Fusion 4 Plus is a fully automatic integrated baler wrapper which can apply film or net wrap to the barrel of the bale, delivering optimum bale shape and bale density. The Fusion 4 Plus can provide high quality fodder through the use of the film binding system, resulting in better silage quality and easier feed out. The machine is equipped with a patented bale transfer system and a vertical wrapping ring. These two McHale patents deliver maximum output whilst keeping the machine short and compact at 5.8 meters.

The new McHale Fusion 4 range has been developed with a focus on operator comfort and machine performance, while still ensuring the renowned simplicity and reliability is maintained.

Our specialist team of engineers have maximized machine intake and output, increased bale density and reduced maintenance intervals to ensure the Fusion 4 range of machines surpasses all your baling and wrapping expectations. These levels of comfort, when paired with proven features such as the patented bale transfer system and the vertical wrapping ring, enable the McHale Fusion 4 range of machines to offer durability, reliability and high-output to the end user.

Film Binding Technology

IN-CAB ADJUSTMENT

The ISOBUS control console allows for bale density to be adjusted from the comfort of the tractor cab. Depending on the crop and conditions, the operator can also adjust the number of layers of net on the control console.

DROP FLOOR UNBLOCKING

The drop floor unblocking system is fitted with an automatic unblocking function as standard. When connected to an ISOBUS tractor, the Auto Unblock feature lowers the floor when a blockage is detected. Once the operator restarts the PTO and clears the blockage, the drop floor will raise to its original position.

AUTO KNIFE DROP

In order to facilitate various feeding methods, McHale have developed a system allowing the outside of the bale not to be chopped. This allows the operator to chop the forage until the bale is almost complete, at which point the machine will automatically lower the knives. This improves machine intake and aids fodder distribution for the farmer.

CONTROL CONSOLES

The McHale Fusion 4 Plus is fitted with ISOBUS as standard. For customers without an ISOBUS tractor, an optional ISO-PLAY 7 or ISO-PLAY 12 terminal can be used. Through the ISOBUS tractor’s terminal or McHale’s ISO-PLAY consoles, the operator is provided with clear indicators of machine performance and allows for increased levels of monitoring, through the graphic display.

CAMERA DISPLAY AS STANDARD

The McHale Fusion 4 Plus comes fitted with a camera as standard to monitor the transfer and wrapping operation at the rear of the machine. When using an ISO-PLAY terminal, this camera automatically displays on the control console in the tractor cab when the bale is being transferred to the wrapping table, at the beginning of the wrapping cycle and when the bale is about to be tipped.

The McHale Fusion 3 is a high output integrated baler wrapper. The Fusion is a purpose built machine which consists of an 18 roller heavy duty fixed chamber baler – delivering a 4′ x 4′ 1″ bale and a high speed vertical wrapping ring.

The machine guarantees the highest output and reliability, through the use of the McHale patented bale transfer, which allows the bale chamber to split horizontally and the lower section of the chamber doubles as a transfer mechanism to transfer the bale to the vertical wrapping ring. the machine has been designed to be compact, maneuverable, and through its patented bale transfer it delivers unrivaled performance.

The McHale Fusion 3 Pro is a fully integrated baler wrapper which is controlled by the iTouch control console. The McHale Fusion 3 Pro provides new levels of operator comfort with its large 7″ touch screen monitor, in-cab net and density adjustment, camera, and faster able wrapping speeds along with a host of other features.

The McHale Fusion 3 Pro uses net to bind the bale in the chamber and features the McHale patented bale transfer and vertical wrapping ring, which are noted for their reliability, speed, and positive bale transfer in hilly conditions.

The McHale Fusion 3 Plus is a high output integrated baler wrapper which incorporates film on film technology. The Fusion 3 Plus features the proven and reliable McHale patented bale transfer and high speed vertical wrapping ring. The Fusion 3 Plus can apply film on film technology, which allows the bale to be wrapped with film in the bale chamber prior to being wrapped with plastic on the wrapping platform. This results in better film coverage on the bale, more even film distribution, superior silage quality and bales which are easier to feed out. The McHale Fusion 3 Plus is also capable of using net wrap to bind the bale in the chamber.